|

|

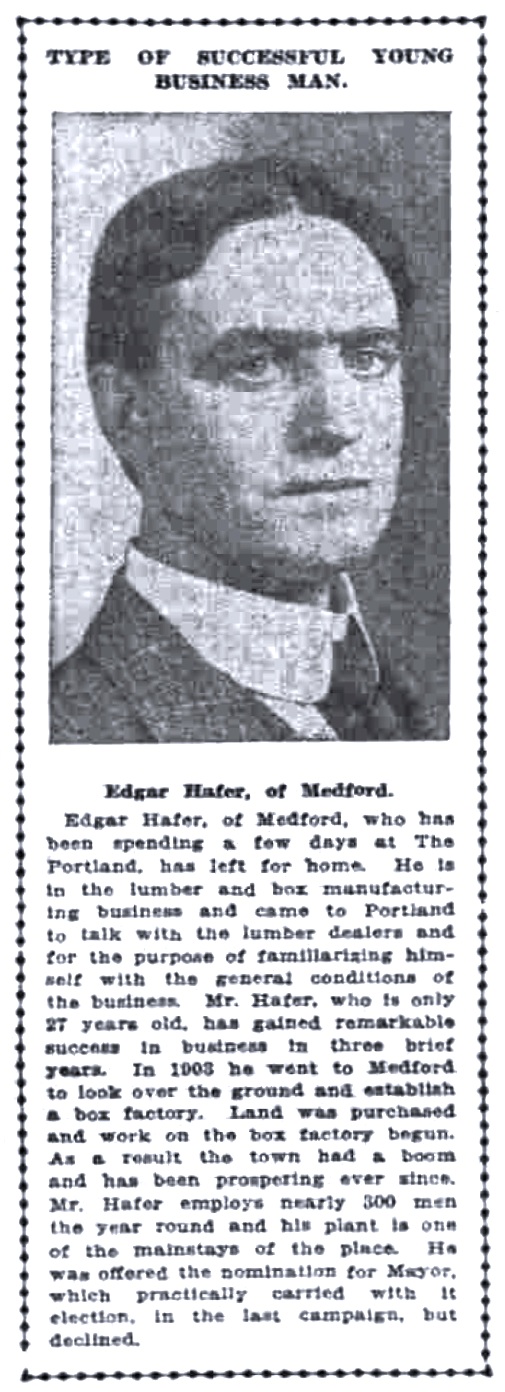

Edgar

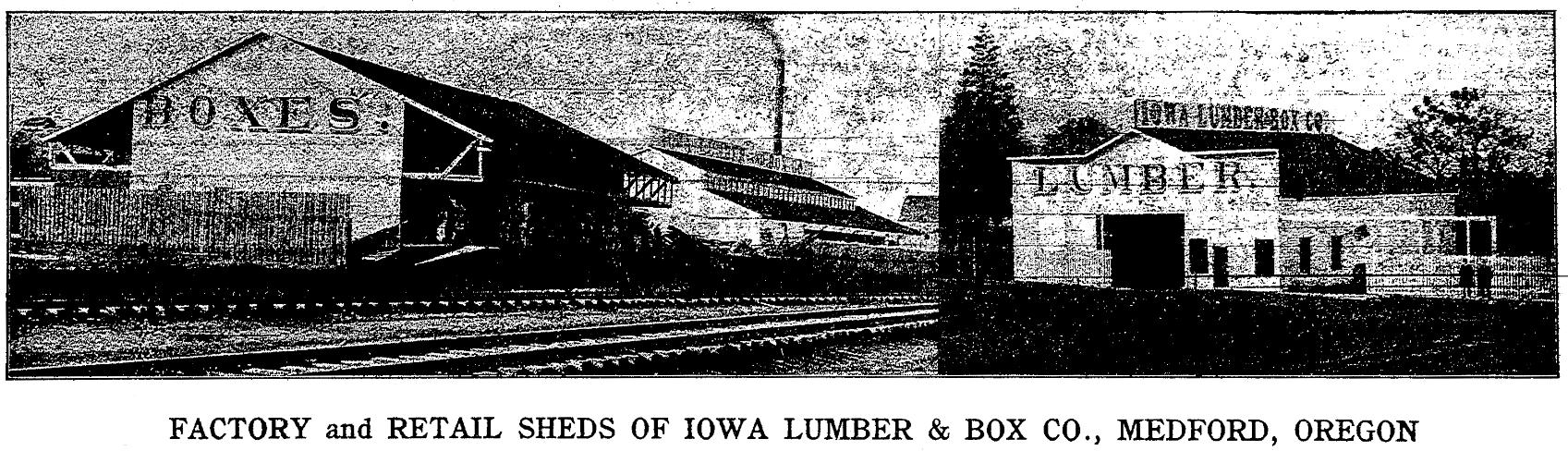

Hafer and the Iowa Lumber Co.  Iowa Lumber & Box Co., circa 1910 Will Boom Things.

The Iowa Lumber Co., who bought the Beekman-Linn timber land three

miles back of Jacksonville, will erect two saw mills with 60,000 feet

per day capacity, extend the branch railroad and put in a box factory,

so manager Williams reports.

Buy Timber and Will

Build Mill.

MEDFORD,

July 8.--The Iowa Lumber Company, of Council Bluffs, Ia., has purchased

1500 acres of sugar, yellow and white pine lumber of Beekman &

Linn, of Jacksonville, and will commence at once the erection of two

mills. The timber is situated one mile from Jacksonville. The work on

the mills and the extension of the Rogue River Valley Railroad to the

timber will be begun at once. The company will erect a box factory,

either at Medford or Jacksonville. A strong effort will be made to

secure it for Medford.

Morning Oregonian, Portland, July 10, 1902, page 4 Preparing To Saw Lumber.

The

Iowa Lumber Co. is making ready with all possible haste to commence

operations in the timber belt which the company recently purchased.

HAVE STARTED THEIR BUILDINGS.This tract of timber embraces 1700 acres and is situated about one mile, at its nearest point, west of Jacksonville. The purchase was made a few weeks since from C. C. Beekman, and the price paid was $15 per acre. It is estimated that there are 25,000,000 feet of merchantable sugar and yellow pine, together with a goodly amount of fir.  The company has one sawmill purchased and expect it

to arrive next week, when it will be put in operation. This mill will

have a capacity of 30,000,000 [sic]

feet per day of ten hours. Another mill of similar character and

capacity will be put in just as soon as it can be gotten here from the

East. It may be found that one shift a day for each mill will not

supply a sufficient amount of lumber, in which event a double, day and

night, shift will be put on.

The company has one sawmill purchased and expect it

to arrive next week, when it will be put in operation. This mill will

have a capacity of 30,000,000 [sic]

feet per day of ten hours. Another mill of similar character and

capacity will be put in just as soon as it can be gotten here from the

East. It may be found that one shift a day for each mill will not

supply a sufficient amount of lumber, in which event a double, day and

night, shift will be put on.The lumber is to be used principally in the manufacture of fruit boxes, and a box factory is to be established at some convenient point in the valley. While the location of the factory has not been definitely settled, it is conceded that Medford will get it--this point being more centrally located and thus more convenient for the distribution of the boxes among our fruit growers and at the same time on the main line of the Southern Pacific railroad and thus easy of access for shipments of boxes to other railroad points of the valley. Mr. John N. Williams, vice president and general manager of the company, together with his wife, is now here and is superintending operations. Mr. Williams is from Boulder, Colo. R. G. Harrison is cruiser for the company and is now at work in the timber. Mr. Ernest E. Hart, president of the First National Bank of Council Bluffs, Iowa, is treasurer of the company. The enterprise which this company has undertaken will prove itself to be of great value to the valley, and everything possible should be done by our citizens to encourage it. These people are right now being handicapped to some extent by not being able to secure help. They want to hire loggers, teamsters and mill men. Medford Mail, July 18, 1902, page 2 Chas. Yates and family, of Boulder, Colorado, arrived in the valley last week and have taken up their residence at Jacksonville where they will be temporarily located. Mr. Yates will be employed by the Iowa Lumber Company and will undoubtedly move to one of the camps of this company as soon as said camps are established. "Purely Personal," Medford Mail, July 18, 1902, page 6 The Ashland Tidings reports the sale of the Rogue River V.R.R. to the Iowa Lumber Co. There is no foundation to this rumor as yet. There is some talk of extending the line to the big tract of timber land recently bought by Messrs. Beekman & Linn by that corporation, however. The Iowa Lumber Co., which purchased an extensive tract of timber land situated west of Jacksonville, recently, is busily engaged in preparations for the installation of a sawmill having a capacity of 3,000 feet of lumber an hour. J. N. Williams, a member of the corporation, has charge of the work, and is assisted by R. G. Harrison and others. The plant, which is coming from the East, was delayed some time while en route to the coast. It is a first-class one, and will give employment to a number of men. Later a box factory, to use the output of the mill, will be erected. "Local Notes," Democratic Times, Jacksonville, July 31, 1902, page 4 The family of H. E. Williams, of the Iowa Lumber Co., will occupy the deBar residence. "Jacksonville News," Medford Mail, August 8, 1902, page 3 The Iowa Lumber Company, which has purchased 1500 acres of pine timber land seven miles southwest of Medford, is making every preparation for putting up a large sawmill plant, planing mills and a box factory. The first carload of machinery has arrived. "Oregon News Notes," The Daily Journal, Salem, August 22, 1902, page 4 The Iowa Lumber Co. will soon be running on full time. It is already manufacturing a large quantity of superior lumber daily. "Personal Mention," Democratic Times, Jacksonville, September 18, 1902, page 4 J. N. Williams, general manager of the Iowa Lumber Company, who recently put up a sawmill on the tract of timber which his company bought a few months since from Beekman & Reames and David Linn, near Jacksonville, reports that the sawmill is now in operation and that a goodly amount of lumber is now on the yard, much of which is being used in the construction of buildings for the company's use. It is the intention of the company, Mr. Williams states, to build a tramway from the mill to connect with the Medford-Jacksonville shortline at Jacksonville. The lumber brought out over this road will be piled in Jacksonville to dry. Upon the matter of the building of a box factory in the valley Mr. Williams was noncommittal. A Mail reporter, however, was given to understand that the establishing of the factory in Medford had not been given up and that when the time came to put in the factory our town would be given a fair, impartial hearing, and if the company could see it to their advantage it would be established here. "City Happenings," Medford Mail, October 10, 1902, page 7 The Iowa Lumber Co. has its plant in fine condition and is running on full time. It is manufacturing a large quantity of superior lumber daily, which finds a ready sale. "Personal Mention," Democratic Times, Jacksonville, October 16, 1902, page 1 Lumbering at Jacksonville.

J. N. Williams, general manager of the Iowa Lumber Company, who

recently put up a sawmill on the tract of timber which his company

bought a few months since from Beekman & Reames and David Linn,

near Jacksonville, reports that the sawmill is now in operation and

that a goodly amount of lumber is now on the yard, much of which is

being used in the construction of buildings for the company's use. It

is the intention of the company, Mr. Williams states, to build a

tramway from the mill to connect with the Medford-Jacksonville

shortline at Jacksonville.

Valley

Record, Ashland, October 16, 1902, page 1

J. N. Williams, manager of the Iowa Lumber Co., which has installed a first-class mill a few miles west of Jacksonville, was in Medford Thursday. They are now running on full time and manufacturing a large quantity of superior lumber daily. "Brief Mention," Democratic Times, Jacksonville, October 23, 1902, page 2 The Iowa Lumber co. have their sawmill, situated near Jacksonville, running on full time now. A large force of men are employed. "Jacksonville News," Medford Mail, October 24, 1902, page 3 The Iowa Lumber Co. recently shipped a carload of lumber to Blackwell mining district, for use at the Bowden mine, where an air compressor will be installed. It will soon be ready to furnish any kind of building material of superior quality. "Brief Mention," Democratic Times, Jacksonville, October 30, 1902, page 2 L. L. Corliss and family and mother and aunt, of Grand Rapids, Michigan, arrived in the valley last week. They are now at the mills of the Iowa Lumber Company, where Mr. Corliss will be employed. "Purely Personal," Medford Mail, October 31, 1902, page 6 The first carload of lumber from the Iowa Lumber Co.'s mill arrived in Medford via the Rogue River Valley Railway on Tuesday. It appeared first-class in quality, was of mixed sizes, principally heavy pieces, and consigned to Gold Hill. "City Happenings," Medford Mail, October 31, 1902, page 7 The Iowa Lumber Co., which is operating near Jacksonville, is making preparations to install a new forty-horsepower boiler, which is expected to arrive in a few days. They have also ordered an engine to be added to their plant, as they have already found the need of more power. When the new machinery is in place an electric plant will be added and the mill run night and day, and during the daylight hours the power used for generating electricity will be utilized in running a lath machine. The company is turning out a large amount of first-class lumber, and the addition to their machinery indicates their intention to turn out more. "City Happenings," Medford Mail, November 28, 1902, page 7 The Iowa Lumber Co. has ordered another boiler from Portland, which will soon be in position. This will enable it to increase its output considerably. A large quantity of superior lumber is already on the yards, which will find a ready market. "Brief Mention," Democratic Times, Jacksonville, December 3, 1902, page 1 Mr. and Mrs. Hart, of Council Bluffs, Iowa, were the guests of Mr. and Mrs. J. N. Williamson, of this city, last week. Mr. Hart is treasurer of the Iowa Lumber Co., now in business here and of which corporation Mr. Williamson is the manager. "Jacksonville News," Medford Mail, December 12, 1902, page 3 O.&C.R.R. to Iowa Lumber Co., 83.64 acres, sec 13, tp 37s, r3w . . . $897 "Real Estate Transfers," Medford Mail, December 12, 1902, page 5 Peter Denhof, formerly of Grand Rapids, Mich., who has been spending several months in Medford, has taken a position as ratchet setter with the Iowa Lumber Company in their mill near Jacksonville. "Additional Local," Medford Mail, December 12, 1902, page 6 The Iowa Lumber Co. has installed a new boiler of the best pattern at its mill, which gives it an abundance of power and enables it to daily turn out several thousand feet of lumber more than previously. "Local Notes," Democratic Times, Jacksonville, December 17, 1902, page 1 Chas. B. Adams, who has been with the Iowa Lumber Company since the plant was established near Jacksonville, was one of the Christmas shoppers in the city Saturday. He expects to mine during the winter. "Purely Personal," Medford Mail, December 26, 1902, page 6 A deed to the Iowa Lumber Co. from C. C. Beekman and D. Linn, for 1541 acres of timber land located a short distance west of Jacksonville, has been recorded in the county recorder's office. The consideration is $23,120, or $15 an acre. "Local Notes," Democratic Times, Jacksonville, December 31, 1902, page 1 The Iowa Lumber Co., which has begun the manufacture of lumber in earnest, with its accustomed enterprise is building a tramway from the mill, which will deliver its product at the railroad. This will not only be a great convenience, but will decrease the expense of handling the lumber considerably. "Local Notes," Democratic Times, Jacksonville, January 7, 1903, page 1 J. N. Williams, manager of the Iowa Lumber Co., whose mills are situated near Jacksonville, was in the city Tuesday upon business. He reports that work is progressing finely at the mill and that he looks forward to a very successful season. He has now a tramway one and a quarter miles in length in operation, and the previous congested conditions at the mill are materially relieved by the sending out of a great amount of lumber over this route to a point one mile from Jacksonville, where the company has secured a site for the piling of the product of the mill until such time as it will be put on the market. The storage yard is easy of access, being near the main thoroughfare. The output of the mill consists almost entirely of sugar pine and California pine. A goodly amount of this is of a superior grade, some of which the company has recently sawed being forty inches wide, sixteen feet long and clear of knots. A carload of this lumber, which is being sawed two and one-half inches thick, is being gotten ready for shipment to Council Bluffs, Iowa, to which place it will be sent as a sample of Southern Oregon products. Calvin Hafer, president of the company, is here from Iowa, and is well pleased with the condition of matters and things generally about the mill. Mrs. Hafer is also in Jacksonville, and while her husband busies himself about the mill she gathers gold nuggets from nearby placer mines, to take home and show her friends--another of the products of Southern Oregon. "City Happenings," Medford Mail, February 20, 1903, page 7 The Iowa Lumber Co., which is constantly adding to and improving its already extensive plant, during the past week received a first-class lath machine, which will enable it to make use of material now going to waste. "Brief Mention," Democratic Times, Jacksonville, March 18, 1903, page 2 J. N. Williams, who is one of the principal stockholders of the Iowa Lumber Co., left for Colorado Saturday, accompanied by his wife. They will be in Council Bluffs for a few weeks and remain some time. We wish them a pleasant trip and hope to chronicle their return home. "Brief Mention," Democratic Times, Jacksonville, March 25, 1903, page 1 The Iowa Lumber Company, of Jacksonville, Oregon, have recently added a lath mill to their equipment. The mill is now cutting 30,000 feet per day. The lumber is run from the mill on a gravity tramway one and a quarter miles in length, to their yard at Jacksonville. Mr. Hafer, of the company, was in this city recently purchasing planing mill machinery. "Along the Southern Pacific," The Columbia River and Oregon Timberman, April 1903, page 14 The Iowa Lumber Co. keeps adding to its machinery, and now has one of the best and most complete plants in Southern Oregon. This week it received a first-class planer, which will be installed at once. "Brief Mention," Democratic Times, Jacksonville, April 22, 1903, page 2 The Iowa Lumber Co. has received a huge engine and boiler, which will be used in propelling the planing machine received lately. It is installing a burner that will consume the sawdust produced at the mill. The company will soon have one of the best and most complete plants in Southern Oregon. "Local Notes," Democratic Times, Jacksonville, April 29, 1903, page 1 The Iowa Lumber Co. has broken ground for a first-class sash and door factory. It will be located on the lot adjoining J. H. Hoffman's residence, on Oregon Street. "Local Notes," Democratic Times, Jacksonville, May 6, 1903, page 1 The Iowa Lumber Co. during the past week received a fine donkey engine, weighing twelve tons, which will be used at its plant. It is constantly adding machinery and making improvements. "Brief Mention," Democratic Times, Jacksonville, May 6, 1903, page 1 ACTIVITY IN THE LUMBER MILL.

Plant of Iowa Lumber Company Enlarged and Put in Successful Operation-- Big Shipments of Lumber Now Being Made--Splendid Work of President Hafer.

Pres. C. Hafer,

of the Iowa Lumber Company, has proven himself to be a hustler equal to

the best and in the right place as president of the leading lumber

concerns of Southern Oregon. It was six weeks ago this Friday since he

landed in Jacksonville from Council Bluffs, Iowa, and in that time he

has accomplished more in the way of getting profitable results for his

company than the previous management had accomplished in the past year.

He found a mill overloaded with men and underloaded with product, the

expense account running far beyond the income; that he has changed, and

the mill is turning out lumber to its full capacity. He brought with

him the complete plant for a large planing mill, that he has

superintended from the laying of the foundation to the successful

starting of the machinery. With no lumber being shipped at all, Pres.

Hafer has had over a quarter of a million feet of lumber placed on the

cars and started to the eastern markets, with still larger quantities

to follow hard after. To this he has added a local trade that has

already brought in some good bills and which is but the beginning of

larger sales. In addition to attending to these matters, Pres. Hafer

has taken a complete invoice of the entire plant belonging to his

company, and he has reorganized the personnel of the payroll, selecting

a crew for the sawmill, the logging camp and the planing mill that are

all competent, industrious men that will get the best results possible

for his company. And while attending to the multitude of details

attendant to securing these profitable results he has had the

anxiety and the sore distress to weight his mind caused by the severe

illness of Mrs. Hafer, to whom he is deeply devoted, and whose severe

attack of pneumonia caused both Mr. Hafer and their many friends deep

concern for several days.

President Hafer is the man that Jacksonville has been looking for; for these many days and now that he has assumed active control of the business of the Iowa Lumber Company this town will receive an impetus to its prosperity that will be far reaching in its results. As to the statements of some wiseacres that this lumber company would be out of here within three months, President Hafer states that he expects to keep their mill running here for more than 20 years yet. He plans that his company will be able within no distant day to put in a railroad to Applegate and to bring the logs from that immense body of fine fir and pine to a big mill in Jacksonville to manufacture into lumber. President Hafer can rest assured that he and his company will have the hearty cooperation of the citizens of Jacksonville in all that will assist in bringing success to their endeavors which means so much to the growth of this town and the development of a very large area of Jackson County. Jacksonville Sentinel, June 19, 1903, page 1 LUMBER COMPANY COMMENCES WORK

The

Iowa Lumber Company now have men at work building a fence around the

Palm-Narregan tract, which has been leased for their purposes. This

tract will be used for a storage yard for the rough lumber. The company

is now getting out material for the building they expect to erect,

which will require some 200,000 feet of lumber. The planer and box

factory will be 60x150 feet and, besides this, there will be a shed for

the storage of box material capable of holding 150 carloads; one for

the storage of dressed lumber capable of holding 100 carloads, and one

for stock to be disposed of at retail. The company's offices will be on

the corner of 6th and F streets, near the depot of the R.R.V.R.R. Co.

Mr. Edgar Hafer, who is in charge of the matter, is very anxious to

commence work on the buildings as soon as possible, as he realizes the

amount of work on his hands. The planer, box factory, storage sheds,

etc. will be placed on the railroad tract between the ice plant and the

vinegar factory, while the Palm-Narregan tract of seven acres will be

used exclusively as a piling yard for the rough lumber. From this yard

the lumber will be hauled by team direct to the machines in the mill,

and as much of the expense of frequent handling obviated as possible.

Instead of a shingle roof, Mr. Hafer is figuring on corrugated iron for

the buildings. It will be a little more expensive to start with, but

more economical in the end. Besides being less liable to be set on fire

by flying sparks, it will make insurance cheaper.

Medford Mail, November 27, 1903, page 1

Mail Office

Devil:--"Say, some o' these people around this town give me a pang.

Honest, they do. Some of 'em 'most die when anybody tries to do

somethin' to help the town along. It like to have paralyzed them when

the soliciting committee succeeded in raisin' that subsidy so easy,

'cause they said it couldn't be done. Now they are afraid the [Iowa]

Lumber Company will go back on the contract and won't build the mill.

'If they do build it,' these fellows say, 'the company will go broke.

There ain't nothin' here to keep a mill,' and all that sort o' stuff.

If that kind of people wuz to git to heaven, they'd commence knockin'

the way the place wuz run, and would grab the first chance to test

their harp, to see whether it wuz solid gold or just gilded. Shucks,

they make me weary."

"Street Echoes," Medford Mail, November

27, 1903, page 1Medford Captures Box Factory.

MEDFORD,

Or., Nov. 17.--(Special.)--The sum of $3000 was raised by the citizens

of Medford today for the purpose of defraying the expense of moving the

box factory and planing mill belonging to the Iowa Lumber Company, now

located at Jacksonville, to Medford. The work of moving will commence

the first of next week. The company has leased a tract of land in North

Medford from the railroad company and private parties, and if addition

to the box factory will establish a wholesale and retail lumber yard.

This enterprise ensures a payroll of at least $50,000 a year, and will

go far towards establishing Medford as the business center of Jackson

County.

Morning Oregonian, Portland, November 18, 1903, page 4 Building a Box Factory.

MEDFORD,

Or., Dec. 11.--(Special.)--The Iowa Lumber & Box Company, of

Jacksonville, has six teams engaged in hauling lumber to Medford for

use in the construction of its several buildings. Nearly enough lumber

is on the ground for the planing mill and box factory, but there is

some hitch in securing a lease from the railroad company.

Morning Oregonian, Portland, December 12, 1903, page 5

The

Iowa Lumber & Box Company has over twenty men at work on the

new

buildings which they are putting up in Medford. Work has been held back

for a few weeks, owing to the inability of the company to secure

concessions and leases of land from the railroad company--but now, when

all matters are understood between the parties interested, all

concessions and leases asked for have been granted, and work is being

vigorously pushed on the buildings.

The IOWA LUMBER & BOX

COMPANYThe local representative of the company, Mr. Edgar Hafer, is doing everything possible to secure an early operation of the plants in Medford. He is just a little busier than any half dozen men in these parts, and every move made brings the work just that much nearer to the end sought. The company has secured a lease on railroad land just west from the Medford-Jacksonville short line depot for their offices and retail yards. A sidetrack will be built alongside of the planer and box factory, thus giving them convenient facilities for shipping out the finished product, either in boxes or surfaced lumber. Nearly all the lumber necessary for the buildings is now on the ground; the old buildings in Jacksonville are being torn down, and the machinery used there has all been gotten in shape to move here; a new 200-horsepower engine, for use in the planer, has been ordered from Indianapolis, Ind.; a carload of box machinery, costing $5000, has been ordered from Chicago. Included in this machinery is one of the finest box-printing machines ever put in operation. Mr. Hafer informed a Mail reporter this week that his company had but recently been compelled to turn down an order for boxes, the lumber in which would amount to over a million feet. It is the intention of the company to manufacture boxes of all description, and as soon as the mills are in operation they will be prepared to book orders. This company has already contracted to purchase the output of the Stensill mill, near Phoenix, which will amount to about two million feet a year, also the output of the Chamberlain mill, near Talent, which will probably amount to one million feet. Besides all this lumber they will have the output of their own mill, which ought to give the factories here about all they can handle, still Mr. Hafer may contract for the output of at least one more mill. If things come anywhere near materialization as the indications now point there will be fully 100 men employed in the Medford mill and factory alone, to say nothing of those at the sawmill. Mr. Hafer tells us that a scarcity of tenement houses in Medford is working a hardship upon five or six of his men, as they are compelled to keep their families in Jacksonville while they are working in Medford. The suggestion contained in the above bit of information will undoubtedly be taken advantage of by some of our townspeople who own city real estate and who have means with which to build dwelling houses. Medford Mail, January 1, 1904, page 1 LUMBER COMPANY'S BIG DOINGS.

The

Iowa Lumber and Box Company is putting in good time in their efforts to

start the wheels to rolling in their big box factory and planing mill.

Work is progressing rapidly these fine days, and with the disappearance

of each day's sun some new piece of machinery has been put in place.

One hundred and twenty-six feet of four-inch line shafting has been hung; four of the large planers have been put in place; line shafting is being put up for the edger and other mill machinery; the sawdust and shavings pipes are being put up; the boiler is now in place; the excavation has been made for the engine, and the concrete work is being put in; the grading of the sidetrack will be commenced Monday. There will be 515 feet of this work to do--which has to be done by the lumber company. They also furnish the ties, and the railroad company furnish the rails and put them down. The carload of box machinery, together with the new engine, has been shipped from Chicago. This engine is of 165 horsepower, under a pressure of 110 pounds of steam. The company has let a contract to S. S. Walsh and E. C. Steiger, of Centralia, Washington, to operate their sawmill the coming season. The contract calls for the sawing of three and a half million feet of lumber. This cut will be made from some of the very best timber owned by the company. A contract has also been let to California parties for hauling this lumber from the mills to Medford. Twenty horses will be used in hauling of the lumber, and Medford will be headquarters for the haulers, they remaining in Medford each night. This will be an advantage to our town, and will be just as convenient for the haulers. The fourteen head of fine draft horses, owned by the lumber company, will nearly all be kept at work about the yards and mills in Medford. Mr. Clarence Hafer, a member of the company, will leave Sunday by way of Portland, for a couple of weeks' business trip to Council Bluffs, Iowa. Medford Mail, January 29, 1904, page 1 WHEELS WILL SOON BE TURNING.

Work at the Iowa Lumber and Box Company's plant is moving along nicely

and if nothing unforeseen bobs up to interfere the wheels will be

rolling by the first of March.The car of box machinery from Chicago has passed Council Bluffs on its way here; the large engine, ordered from Indianapolis, is now in Portland awaiting reshipment to Medford; Mr. Edgar Hafer left Medford yesterday for Portland, where he will purchase a couple of additional machines for the box factory, and these and the engine will at once be forwarded here. While in Portland Mr. Hafer will purchase a carload of sash and doors--for immediate shipment to Medford. The concrete foundation for the engine and boiler will be completed this week, and work on the sidetrack is progressing finely. Persons familiar with planing and box factory plants on the Pacific Coast, who have seen the plant being put in by this company, have no hesitancy in saying that it will unquestionably be the best plant between Portland and San Francisco. Medford Mail, February 12, 1904, page 1 Mr. and Mrs. Clarence Hafer arrived in Medford Monday from Council Bluffs, Iowa. Mr. Hafer, who is connected with the Iowa Lumber and Box Company, left about three weeks ago for Council Bluffs and Kansas City, but only a very few knew that his mission to the East was that of taking unto himself a life helpmate. Such, however, was the case, and on the 10th of the month he was married to Miss Emma Lee Griffith, of Kansas City. These young people will make Medford their future home, and are now very cozily ensconced in pleasant rooms in the Palm-Bodge block, which Mr. Hafer furnished very elaborately prior to going east. "Purely Personal," Medford Mail, February 26, 1904, page 4 Two carloads of machinery arrived this week for the Iowa Lumber and Box Company, and it is now being unloaded. All the other machinery is now in place, and it is expected that the engine will be set and wheels turning by the 8th or 10th of March. The company has recently acquired property, to the north of the planing mill, upon which they will build a large platform to be used for grading lumber as it comes from the sawmills. Work on the larger storage sheds will commence soon. These sheds will be sufficiently large to hold seventy-five carloads of lumber, and by having sheds of this capacity there will be little trouble experienced by the possibility of being compelled to shut down the mills in case of a shortage of cars. Manager Edgar Hafer informed a Mail representative Tuesday that in all probability the company would start the plant with forty men on the payroll in this city--and this number may be increased to fifty. The positions have all been filled except those for common labor. Four or five mills in various parts of the county are now cutting logs preparatory to supplying the factory here with lumber. J. E. Olson is among the latest to contract for the delivery of lumber, and he is now logging pine timber for that purpose. The company has agreed to take all his first-grade pine lumber. "City Happenings," Medford Mail, February 26, 1904, page 5 Oregon Chapter No. 4, R.A.M. gave their annual banquet and reunion Thursday. . . . Mrs. C. E. Hafer, who recently came to Medford, the bride of Mr. C. E. Hafer, of Kansas City, made her first appearance before a Jacksonville audience. Mrs. Hafer has a round, full voice, finely cultivated, and her solo was one of the most enjoyable features of the evening's entertainment. Jacksonville Sentinel, supplement, March 11, 1904, page 1 The Iowa Lumber & Box Company, of Medford, are getting out an order for 100,000 cannery cases for California, which will take 600,000 feet of lumber. The orders now taken by the company amount to 200,000 boxes, and will consume 2,000,000 feet of lumber. The Iowa Box & Lumber Company of Medford have their box factory and planing mill in operation. The company operate a mill in their timber about six miles from Medford, and have two other mills under contract, which will give them an output of 75,000 feet daily. The factory is well equipped with modern tools for handling their cut, which consists of boxes, cut-up factory stock, lap siding and finish. Their upper grades are shipped to their eastern branch yards at Council Bluffs, Iowa. The boxes find a market locally and in California. A storage shed 180x100 will be constructed at once. A receiving platform with an edger will be installed, where the clear strips will be cut out before going to the factory, to eliminate rehandling, and ensure uniform grading. The company's piling yard, containing seven acres, is located north of the factory, where their stock is carried. A retail yard and shed is located conveniently to the factory, where the offices of the company will be maintained. A sidetrack will enter the yards, and a dry kiln will be constructed later in the year. Their timber holdings, owned and under contract, aggregate about 40,000,000 feet, and consist of fir, sugar and white pine. A Willamette road engine and a Puget Sound Iron & Steel Works yarder are used in the company's logging operations. The officers of the company are: C. Hafer, president; E. E. Hart, treasurer; Edgar Hafer, manager. Manager Hafer has started a young zoological garden, and has a pair of young deer in an enclosure for the edification of his guests who have strong deer hunting propensities. With a Matt Saley pacing mare Mr. Hafer's joy will be complete. Clarence Hafer, a new benedict brother, looks after the mechanical end of the factory. The company have plenty of orders, and manager Hafer feels proud of the success which has attended his efforts in his new western home. More power to his elbow. "Southern Oregon," The Columbia River and Oregon Timberman, April 1904, page 20 Been Doing Business All the Time.

The

Iowa Lumber and Box Company is not parading our streets with brass

bands or flying banners heralding the fact that it is still doing

business at the old stand. Instead the company has been keeping its

wheels constantly rolling since last March, and the amount of work

which has been turned out, and lumber which has been manufactured from

the monster pines of the virgin fores into useful articles of commerce,

is almost beyond comprehension.

Since the mill and factory started on March 7, 1904, over five million feet of lumber have been handled. This, considering the fact that it is the company's first season, is indeed remarkable, and no little amount of credit is due manager Edgar Hafer and his able corps of co-workers. The company has just finished a shipment of nineteen carloads of raising boxes and is now working on an order for orange boxes. There is a standing order booked for all of this kind of boxes they can turn out, and right now there are 100,000 boxes in the storage house, ready for shipment. Several carloads of choice sugar pine finish lumber is also being prepared for shipment to Council Bluffs, Iowa, where the company has wholesale and retail lumber yards and where Oregon sugar pine brings fancy prices. There are nearly three million feet of lumber in the sorting and piling yards at this time, and in the opinion of manager Hafer this will very nearly keep the plant running until hauling can be resumed next season. It is quite probable that the plant will close down during the month of January and possibly part of February. This, however, will depend upon the weather. Should there be as much rain as there usually is at that season of the year, this short rest will be taken. While all the machinery is under cover and can be operated in any kind of weather, the lumber is outside and it does not pay to handle it while wet. There has been so much of a hurrah and hubbub about the plant since it started--filling rush orders and giving different workmen a "try-out"--that little time or attention has been given to cleaning up refuse and straightening out lumber in the yards adjacent to the mill, but now there are several men sorting, piling and covering this lumber and making things more presentable generally. The retail yard is also being put in better condition. The sheds are being partitioned off and scaffolding put in to accommodate moldings, sash and doors and all the different kinds of finishing lumber. The company also has men at work now moving their sawmill from the old stand over the mountain to the Jackson Creek side. The mill will be reset on what is known as Lily Prairie. At this setting the company figure they can cut five million feet. The work of moving over the mountain is no small job, but the work is progressing finely. A donkey engine is being used to pull the machinery up the mountain and to let it down on the other side. Over 5000 feet of wire cable is used upon the job. Medford Mail, November 25, 1904, page 1  Medford Mail, March 9, 1906 The Timberman--published at Portland--for January has two good views of the Iowa Lumber & Box Co.'s plant in Medford, together with a short article from manager Edgar Hafer on the timber prospects of Southern Oregon. "City Happenings," Medford Mail, February 3, 1905, page 5 The Iowa Lumber and Box Company is erecting a 16x18-foot ice house, near the Presbyterian Church, upon land owned by C. W. Palm. The ice house will be used to store ice for the Neuber & Hutton saloon, which expects to soon be opened, on North D Street. "City Happenings," Medford Mail, February 10, 1905, page 5 Edgar Hafer, manager of the Iowa Lumber & Box Company, of Medford, spent a few days in Portland recently. Mr. Hafer says the outlook for business in his section of Southern Oregon is good. His company makes a specialty of boxes, and has facilities for working up 30,000 feet of box lumber daily. The upper grades are shipped to the company's retail yards at Council Bluffs, Iowa. About 15,000,000 feet of pine will be handled this season. "Southern Oregon Mills," The Oregon Timberman, May 1905, page 40C History of What Has Been Done During the Past Two Years, and Outline of Work Contemplated for 1905

For a few days

over fourteen months the factory whistle of the Iowa Lumber &

Box

Co. has marked the hour of seven in the morning and six in the evening,

and during that time it has developed from an experiment into a paying

institution.

At the time the question of raising a subsidy of $33,000 to induce the company to move its plant from Jacksonville to Medford was brought up, there were people in this city who expressed the opinion that the enterprise would not be a success and would be of little, if any, benefit to the city. A brief recapitulation of the history of the company will show whether they were right or not. The Iowa Lumber & Box. Co. was organized as the Iowa Lumber Co., and its officers were: C. Hafer, president; E. E. Hart, treasurer; H. D. Forsythe, secretary; J. H. Williams, manager; R. H. Harrison, superintendent. The company purchased a tract of land near Jacksonville, and in March, 1902, the construction of the sawmill was commenced. Williams as manager and Harrison as superintendent remained in charge until June 1903, and during that time the company lost several thousand dollars. In March 1903, the construction of a planing mill was commenced on Jackson Creek and completed by July 15th. This also proved a losing venture. On July 6, 1904, Edgar Hafer, who had previously had charge of the company's retail yards in Council Bluffs, succeeded Mr. Williams as manager and came west to take charge. Finding it impossible, owing to lack of transportation and other facilities, to make the factory pay at Jacksonville, Mr. Hafer conceived the idea of moving to Medford. At the October meeting of the company in 1903, at which time a reorganization was effected and the present name adopted, he laid the matter before the directors, but for a time they were inclined to throw the whole matter up. They had lost much money and didn't see where returns were coming from. They wouldn't talk about a box factory, and it was only by hard work that they were induced to consent to move to Medford, providing the citizens would subscribe $3000 toward moving the plant, and allowed the order for machinery for the box factory to be made. The question was brought up in a public meeting in Medford, and the subsidy was shortly raised.  This agreement was reached November 17th. On December 24th, excavations for the factory building were commenced and on March 7, 1904, within seven days of the time specified in the agreement, the whistle of the Iowa Lumber & Box Co.'s mill engine was heard for the first time in Medford. This delay would not have occurred had it not been for adverse weather conditions. It rained and rained--and then rained--all through January and February, until eight horses were hitched to one wagon, many times, to haul a piece of machinery from the cars to the mill, and at that they were often mired down. The original plant at Jacksonville consisted of four machines. Since then a complete box-making plant has been put in, fact is was ordered before the move was made, and started very soon after the plant was established here. From a doubtful proposition, by energy and business ability it has become a paying enterprise. Since the factory was first started here its capacity has been doubled, and the outlook indicates that more increase will soon be necessary. The buildings now comprise the office and retail lumber shed, 64x100 feet; box factory, 80x192; storage shed, 40x64; carpenter shop, 30x50. A 12-foot platform runs all around the factory and storage shed, and the loading platform is 600 feet long. The company has now under contract the entire cut of the following sawmills: Welch Lumber Co., Spikenard; Chamberlain Bros., Talent; Missouri Lumber Co., Climax; the two mills of Kesterson & Selsby on Evans Creek; W. A. Conger mill at Wilderville and M. A. Wertz mill at the same place. The combined cut of the above mills, including that of the company's mill at Jacksonville, will aggregate 12,000,000 feet--about 600 cars--and must be on the railroad during the next six months. Last year the company worked up 6,000,000 feet of lumber--making some 300 carloads of the finished product. Within the next two weeks every stick of that lumber will be gone. This year they have twice that amount of raw material. Most of the surplus of first grade--that not used in local consumption--is shipped east, where a good trade is being worked up. In 1904 the company shipped 60 carloads of box shook [wooden box parts], all told, to California. That was their first year in the business. This year it will be different. A short time ago Manager Hafer made a short business trip to California, and during that time he contracted $50,000 worth of box shooks to parties in that state. One order alone amounted to $25,000, and he had to compete with the California Pine Box combine. This amount of box shooks will fill 100 cars, as against 60 last year. Nor is this all. These orders are outside of the orange and lemon box business, which is a great factor in itself, and Mr. Hafer informs The Mail that he expects to send out as many more carloads of orange and lemon boxes. The company has had inquiries from the government regarding clear sugar pine lumber for shipment to Manila and have already furnished one carload for that purpose. As soon as the upper Rogue River timberlands are opened up by the building of the railroad now being constructed, there will be a ready market for all the sugar pine timber that can be gotten out. During the past winter the Jacksonville sawmill was moved to a better locality, and there are now 1,500,000 feet in the yards for the transportation of which contracts have been made with the Rogue River Valley Railroad. In the summer of 1904, Mr. Hafer realized that their yard facilities, while large, were not sufficient to accommodate the constantly increasing business, and in the latter part of March this year the J. H. Chambers yard was purchased by the company, in order that room might be had for handling the immense amount of lumber to be brought in this season. The intention is to run a spur track into this yard and put in 1500 feet of tramways in order to facilitate the handling of the lumber expected to arrive soon. This improvement will be made in a very short time. The Iowa Lumber & Box Co. now has the best-equipped box factory between Portland and McCloud, Calif. It is admitted by all mill men that they work their lumber closer--have less waste--than any mill on the coast. This comes from using the eastern methods of saving lumber. It has been necessary to learn economy in this line in the East, more so than on the coast. In the agreement entered into between the company and the citizens of Medford, at the time the subsidy was made, the consideration upon which subscriptions were solicited was that $40,000 per annum was to be expended for labor by the company. During the first year the company has been operating in Medford $50,000 was expended--$10,000 more than the sum agreed upon. In the month of April the payroll amounted to $7,500, and besides this there is some $5,000 due to the several tributary sawmills for material furnished. At the present time there are 250 men employed at the various tributary sawmills, besides those employed in the factory here. During the coming season 100 men will be employed in the factory alone. The company officers now are: C. Hafer, president; E. E. Hart, treasurer; Edgar Hafer, manager; Clarence Hafer, assistant manager. Those in charge of the various departments of the plant here are: A. H. Miller, chief clerk; Robert Telfer, foreman of the retail yards; R. R. Cook, foreman of box factory; G. L. Schermerhorn, foreman of contracting and building; Wesley Green, foreman of receiving and piling yards; E. C. Staggers, foreman of Jacksonville mill. The coming of the Iowa Lumber & Box Co. to Medford has increased the population of the city several hundred, has furnished employment to a number of our citizens, has caused the disbursement of a considerable sum monthly in the city and has generally tended to build up the town. The Mail does not claim all the credit for securing this enterprise for the town, yet it did do something toward it; but the course of this paper has been so consistent in matters of this kind that it has become almost monotonous and people expect it as a matter of course. Every move toward public progress receives the hearty support of this paper and always will, so long as it continues under the present management. Medford Mail, May

26, 1905, page 1

Medford Mail, May 26, 1905

It is understood that the old Sugar Pine Sash and Door factory at

Grants Pass will be started up again by the California Pine Box

combine, which owns the property. This is the direct outcome of the

attempt of the combine to force the Iowa Lumber & Box Co. out

of

business by causing a raise in freight rates. . . .

"City Happenings," Medford Mail, July 7, 1905, page 5 Last week the Mail made mention of a number of new buildings constructed for and being built but did not get the facts concerning the Iowa Lumber & Box Co.'s contracting department. At present the company is putting an additional story upon Attorney Purdin's residence and has contracted to erect the building for the vinegar factory--mentioned last week. This structure will be 50x56 in size and will be rushed to completion for use this season. They also have the contract for remodeling the Hotel Nash, which will consist of throwing the present lobby and the bar into one room, to be used for office purposes, and removing the bar to the room now used as a billiard parlor. A new and modern barn is to be erected on the Erdman farm, east of town. The company is just finishing a 10x80 storage shed and warehouse, for the storing of box material. This makes the fourth addition in the way of buildings that they have made to their plant during the past few months. All this construction work is under the supervision of G. L. Schermerhorn. Manager Edgar Hafer said to a Mail reporter this week, in relation to the business: "We are working full time in the factory and will continue to do so as long as lumber comes in as it has been coming lately. Last Friday and Saturday we unloaded and stacked in the yard 200,000 feet of lumber, and if nothing happens we will be receiving lumber in large quantities for sometime to come. This lumber comes principally from Josephine County mills we have leased and those upon Evans Creek. I don't care to say a great deal about the fruit box business, but you can say that five of the largest growers of apples in the county have contracted with this company for their boxes for the next three years at an agreed price. These boxes will cost them a cent apiece more than they could get them from another concern--but believing--like all loyal Americans should--in patronizing home industry, they are content to do this. At the same time they are getting a better box than ever before and at a lower price that they paid before the Iowa Lumber & Box Co. commenced doing business here. These orchardmen are: E. J. DeHart, Gordon Voorhies, C. H. Lewis, E. E. Hopkins and J. W. Perkins. They represent, perhaps, the majority of the acreage in fruit in this vicinity. I am hopeful of making a contract with the Fruit Growers' Union, as I believe if they consider matters carefully they will realize that the difference in prices between ourselves and our competitors will be more than counterbalanced by the good results following the patronizing of a home industry. "Building in Medford," Medford Mail, July 21, 1905, page 1 SOLD 400,000 ORANGE BOXES

Manager Edgar Hafer, of the Iowa Lumber

& Box

Co., returned Friday from a three weeks' visit to Southern California.

During his absence he closed a contract for the delivery of 400,000

orange boxes to one concern, and he has other orders equally as large

as this in sight and which he hopes to land later. This one order alone

will consume two million feet of lumber; and its money value reaches

better than $50,000. These boxes are to be delivered during

November, December, January and February, which will enable the factory to run continuously during the coming winter.In speaking of other matters relating to lumber and sawmills, Mr. Loafer informed a representative of the Mail that his company had over a million and a half of lumber at their mill near Jacksonville. This mill, during the past four months, has cut a little better than two million feet of lumber, but it will have to soon close down, as the company does not want to saw out more lumber than they can get to the factory before wet weather sets in. The factory is at this time five or six carloads behind on orders now booked for dried fruit boxes. An average of one carload of different kinds of boxes is being daily shipped out, and the amount of rough lumber received daily will exceed 100,000 feet. Mr. Hafer estimates that when winter sets in, or rather by the time the roads become too wet to haul over, there will be more than 5,000,000 feet of rough lumber in the factory yards. This amount will keep the factory running full time during the entire winter. There are now employed, in Medford alone, by this company, between seventy-five and one hundred men. Pretty good payroll, if anyone should ask you--and the best feature of it all is that it is not for a day, a month, or for a year, but in all probability it will be for a period of time even up with the supply of lumber. Fred Renicke has been promoted to the position of factory foreman, he taking the place of R. R. Cook, who so unceremoniously hied himself to Grants Pass and took a similar position with the box combine concern at that place. Mr. Renicke is a thorough, practical factory man and will unquestionably fill the bill to the entire satisfaction of his employers. Medford Mail, September 1, 1905, page 1 I.L.&B. CO. TO INCREASE

PROFIT

While Manager Edgar Hafer was in

Portland a couple

of weeks ago he made the purchase of considerable new machinery for the

box factory of the Iowa Lumber & Box Co. Among the purchases

made

was a new engine boiler of 100 horsepower capacity. This boiler, when

it arrives, will be placed alongside of the boiler of the same size

now in use, and when these are connected they will furnish power jointly

to the 200-horsepower engine which is now in use. The other new

machinery being put in makes this added power a necessity.Another improvement to the factory will be the new blower which he ordered and which will be installed at once. This new blower system is a very late model and will be capable of handling every particle of sawdust and all the shavings which will come from all the different machines. The blower now in use not having sufficient power to do this work, the factory floor is oftentimes badly littered. To give our readers an idea of the magnitude of the new system we will state that 33 horsepower will be required to operate the blower. Another new resaw was also ordered and will be added to the already well-equipped factory. With this new resaw Mr. Hafer expects to be able to increase the output of the box factory at least 10,000 feet of lumber per day, making the total output of the factory alone fully 40,000 feet daily. With this added machinery the box factory and planing mill will easily turn out 50,000 feet of a manufactured product each day. When the planing mill and box factory was put in one year ago last March its daily output was 15,000 feet of lumber. It is now 40,000 and will be increased to 50,000. What will be its output five years from now at this rate of increase? Some of you fellows who may have optimistic ideas figure on it. Along with the other improvements being made by this company is a large carpenter shop in which will be employed continually from ten to twenty men in manufacturing wood into all manner of furnishings used by house builders. Machinery will be installed for this work and power will be taken from the factory engine. Mr. Hafer estimates he will have fully fifty horsepower to use for this purpose, the factory using only about 150 horsepower of the 200 which will be available when the new boiler is installed. At the present time this company is paying out monthly for labor employed in Medford alone a little more than $5000; to mill hands outside of Medford fully another $5000, while the amount paid for lumber this season will reach $100, 000. Medford Mail, September 22, 1905, page 1 The Iowa Lumber & Box Co. has taken a contract for the erection of a 24x28-foot residence for Joseph Bowles, northwest of Medford. There will be large front and back porches and it will cost about $500. This company has also taken a contract to build a barn on the Erdman-Hazelrigg farm, north and east from Medford. It will be 22x48 feet in size. The old barn will also be re-covered--all to cost $400. "City Happenings," Medford Mail, October 6, 1905, page 5 The Iowa Lumber & Box Co. has received the new machinery spoken of a few weeks ago, consisting of a new, complete and up-to-date blower system, a 100-horsepower boiler and resaw. The installation of this new machinery requires that the box factory, to accommodate it, be remodeled and added to. All that part of the present structure north of the boiler and engine room will be removed and a new building 48x64 feet in size will take its place. This will give the company a factory room 80x224 feet in size--and all of it will be full of box factory machinery. Monday work was commenced placing electric lights in the factory, preparatory to running night and day. This wiring is temporary in its nature and only intended to be used during the present rush, and will be replaced by permanent fixtures when the contemplated changes in the factory are made and additional machinery already provided for has been installed. "City Happenings," Medford Mail, October 13, 1905, page 5 At noon Monday, when a high wind was blowing, the sound of the fire bell sent a thrill of alarm throughout the city. The fierce wind, and the dryness on everything capable of being burned, made favorable conditions for a big conflagration. It was there that the wisdom of the Iowa Lumber & Box Co., in putting in fire fighting apparatus of their own, was made manifest. The fire was in the barn of the company, having caught from sparks supposed to have come from the ice plant, and within a very few minutes the company's hose cart was on the ground, playing a stream on the fire. The city department was prompt and arrived just as the fire was extinguished, but that few minutes, under the circumstances, might have given the fire such a start that it would have been impossible to save the building or surrounding ones. "City Happenings," Medford Mail, November 3, 1905, page 5 Clarence Hafer:--"The Iowa Lumber & Box Co. is now shipping a couple of carloads of orange box shooks per day and have been doing so right along for some time. I want to lay the blame for this state of affairs to the person to whom it belongs in a great measure, and that is to Fred Reniche, our factory foreman. During the five months that he has been with us, he has manufactured and shipped 118 cars of boxes, besides the local trade, which was no small item during the packing season itself. It's a record to be proud of. In January, which is usually a dull month in the box business, the average output was close to a car and a half per day. I'll have to attribute a whole lot of that showing to the foreman, because he is a good one and no mistake." "Street Echoes," Medford Mail, February 16, 1906, page 1 Mr. and Mrs. Clarence Hafer leave the latter part of this week for Council Bluffs, Iowa, where they expect to remain for the next year at least. The many friends these young people have made during their residence in Medford will regret their departure exceedingly, but have the consolatory knowledge that nobody ever left Rogue River Valley after a residence for any length of time and stayed away. The boys at the mill are also sorry that Mr. Hafer is leaving them. Although business all the way through and a strict disciplinarian, he has made himself popular with his employees by his approachable disposition and his desire to do justice to all and favor none. "Purely Personal," Medford Mail, February 23, 1906, page 5 QUICK ACTION SAVES FACTORY.

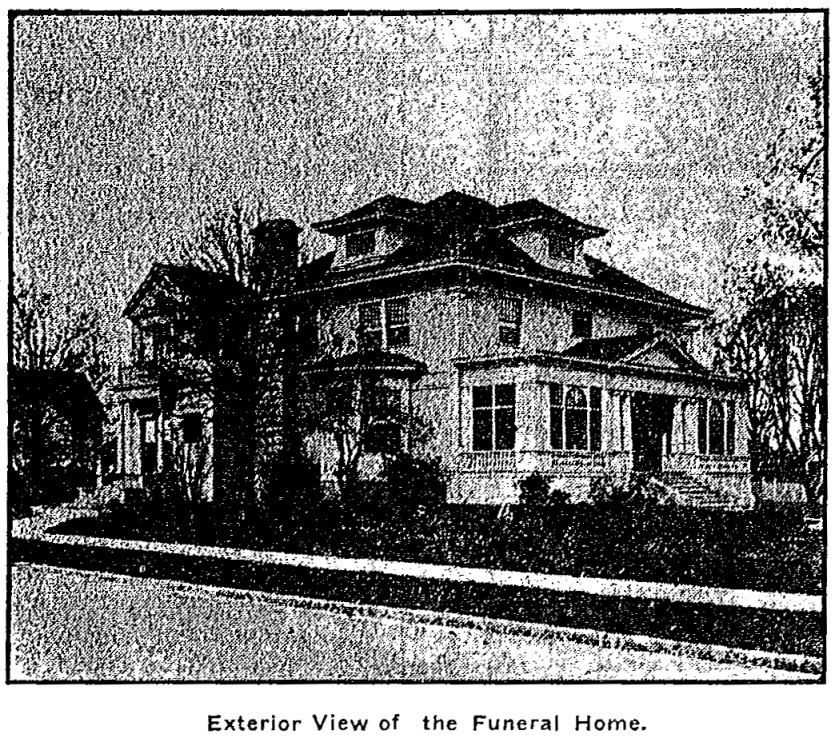

For a short time Tuesday afternoon, between four and five o'clock, the

plant of the Iowa Lumber & Box Co. was in imminent danger of

destruction by fire.The warehouse of the company, which was packed full of box shooks--and this very packing probably saved the building by obstructing the draft--caught fire underneath the floor at the north end. How long the fire had been smoldering is unknown, but when first seen flames and smoke were issuing from the roof. Manager Hafer and Mr. Williams were the first on the scene and Mr. Hafer climbed at once to the second floor of the building, where the smoke was so dense he could see nothing, and with a fire extinguisher held the fire in that part in check until water could be turned on. Other machines were brought into play and the fire department arriving promptly the fire was soon under control. It was quick action and nerve on the part of the factory people; however, that averted a serious conflagration, as with the high wind which was blowing the fire would have spread to the whole plant and to many residences nearby. The loss will be between $2500 and $3000, covered by insurance in the Queens and Royal Insurance Companies. The principal damage was to the box shooks stored in the building, many of which were totally ruined, on account of being stained by the smoke and soaked with water. The suppositious origin of the fire is that some hobo had spent the night under the building and had left a cigarette or coals from his pipe smoldering in the debris beneath the platform. That the fire started from below and upon the inside is shown by the condition of the walls and sills. The sill where the main part of the fire was is charred to the depth of an inch or more and the inside of the wall is also charred from the floor to the roof. On the outside there is no trace of fire. The day of the fire the Iowa Lumber & Box Co. had received a new chemical engine with a hundred feet of hose, but at the time of the fire the engine had not been charged. Now it is ready for business and capable of coping with any ordinary blaze. Medford Mail, May 4, 1906, page 1 Work is progressing finely on Edgar Hafer's new residence. This, when completed, will be the finest home in all Medford. There isn't a thing left undone which will add to its beauty and convenience. "City Happenings," Medford Mail, May 18, 1906, page 5 AT THE BOX FACTORY.

Boxes and then some more boxes, and then some. Apple boxes, orange

boxes, pear boxes, peach boxes and just boxes are stacked up everywhere

at the Iowa Lumber & Box Co.'s factory. Carloads of lumber are

being unloaded and fed to the hungry machines and more boxes turned

out, cars are being loaded with the finished product, consigned to

nearly every point on the coast where such material is used.At present the company has orders on the books for at least forty carloads of box shooks for immediate delivery and are shipping as fast as cars can be secured. The orders are all ready to be filled, but the shortage of cars interferes. However, the company is getting its share and has no complaint to make on that score. Manager Edgar Hafer said to a Mail reporter: "Not only is the box department crowded with orders, but every other department of the business is running now to its fullest capacity. We are employing in the neighborhood of 300 men now in the factory and at our mills, and still want teamsters and heavy teams. Our payroll last month was $10,000, and will be about that for some time yet." There aren't any quiet places about that factory. Everybody and every machine is moving and moving to a purpose, and if the looker-on stands too long in one place he is likely to get run over. Medford Mail, August 24, 1906, page 1  August 14, 1906 Oregonian The Big Bend Milling Co., which is composed of W. I. Vawter, A. A. Davis, Geo. W. Howard and others, has sold its timber holdings in the Big Butte and Rogue River districts. Nearly 6000 acres were sold to the Iowa Lumber and Box Co. and the balance, amounting to nearly 2000 acres more, was purchased by parties interested in the Butte Falls Lumber Co. The terms are private, but the transaction was the largest ever consummated in Southern Oregon and involved a large sum. "A Brief Record of Local Events," Rogue River Courier, Grants Pass, October 19, 1906, page 5 Edgar Hafer:--"The car shortage, so far as the Iowa Lumber & Box Company is concerned, has to a certain extent been relieved. Last week there seemed nothing to do but close the mills, but we have received four cars thus far this week, which makes it possible for us to keep going for a few days. We are nearly buried in manufactured product at the mill, hence the failure to get cars places us in very bad shape." "Things Told on the Street," Medford Mail, December 7, 1906, page 1 TRADE IS PARALYZED

Medford, Or., Sept 28.--As a result of the proposed advance in the

eastern rail rate on lumber, the Iowa Lumber & Box Company's plans

for an immense lumber plant here will be abandoned, the Pacific Eastern

will probably not be extended to the Butte Creek forests and the large

timber tracts adjacent to the Rogue River Valley be left uncut for many

years. This proposed rate will affect every lumber industry in Southern

Oregon, as well as in Oregon in general, and indirectly every business

in the country.New Lumber Rate Is a Deadener on Operations in Southern and Western Oregon. (Portland, Oregon Journal.) Edgar Hafer, of the Iowa Lumber & Box Company, stated today: "It was our intention to make extensive improvements, including the building of a modern sawmill with a capacity of 150,000 feet per day and a new box factory with a capacity of 75,000 feet per day. These improvements alone would cost $250,000, but, with the proposed eastern rates staring us in the face, we certainly shall do nothing, and the only fact we regret is the large amount of capital which we are compelled to allow to lay dormant under existing conditions. "You ask me why the Pacific Eastern is not being built as contemplated and whether the failure of the Oregon Trust Savings Bank will have any permanent effect on its extension. As to this question I cannot answer, but do know as long as there is no lumber company contemplating the opening up of the Rogue River and Butte Creek timber to assure the railroad tonnage, it would be folly on their part to make any further extensions without the assurance or guarantee of a tonnage which would warrant a reasonable rate of interest on the investment. "The mills in Southern Oregon and the Willamette Valley are compelled to find a market in the East, as they cannot get into San Francisco and bay points on the present rate of $5 per ton, which is equivalent to $8.33 per 1,000 feet, and compete with the water rate, which is $4.25 per 1,000 feet from Portland, the Columbia River and Washington points. "The advance in the eastern freight rate of 10 cents per 100 pounds makes it impossible for the lumber manufactured in the southern states, known as yellow pine. "In order to demonstrate the conditions let us take a mill manufacturing lumber in Southern Oregon or anywhere in Western Oregon for that matter and see what the advanced rate means. The rate to Omaha is now 50 cents per 100 pounds against a rate of 23 cents per 100 pounds from southern mills, and it will be advanced November 1 to 55 cents. "Basing a mill cut of lumber at a reasonable value of $15 per 1,000 feet, f.o.b. cars, and adding the 55-cent rate, which amounts to $18.33, makes the lumber cost $33.33 in Omaha. The present value of stumpage is about $1 per 1,000 feet, against the present value of southern yellow pine stumpage, which is about $4. Therefore, the cut of southern yellow pine lumber would be worth $3 per 1,000 more, or about $18 per 1,000 f.o.b. cars mill. Figuring their freight rate of 23 cents to Omaha, which amounts to $7.66, would make the value of southern lumber f.o.b. cars Omaha $25.66, against ours of $33.33, which shows conclusively that it is out of the question for a Southern Oregon mill to compete with them even if the cost of stumpage and the sawmill manufacture was thrown in, as you can see for yourselves the fabulous profits which can be made by the southern yellow pine mills above the basis of $18 at their mills. "Now we will take up the Chicago rate. Our rate is now 50 cents, which will be advanced to 60 cents on November 1, against the Southern yellow pine rate of 25 cents. This makes a difference of $8.66 per 1,000 feet, taking the same basis of price f.o.b. mills, which is even greater than the Omaha advance. "Coming closer home, let us look at the Denver and common Colorado points which has been 40 cents per pound, against the rate from the South, which is 34 cents. The railroad is not content with taking from the Oregon lumber mills the Central States market, but has swooped down upon the Coast mills even in Colorado, where they propose to raise the rate November 1 to 50 cents per 100 pounds, which is 50 percent greater than the southern yellow pine mill rate. "These are the actual conditions which confront the lumbermen of Southern Oregon, as well as Oregon in general, and it is certainly not a very cheering prospect. If the railroads had been bankrupt, or the net earnings had been too small to give a fair rate of interest on their investment, there might be some excuse for the advance. You say, then, why is the rate raised? I do not know, but candidly think that the real reason for the advance is either the desire on the part of the railroad to buy its structural material at its own price by eliminating competition, or it may be regarded as the easiest means to get rid of a surplus of business, which would require considerably more rolling stock than they care to equip their lines with at this time. As a quick and ready plan for destroying the prosperity of the lumbermen, the intended advance rate, however, will certainly do the business. "The effect upon the country by this cold-blooded and coolly calculated plan of the railroads to curtail the output of the greatest industry of the Pacific Coast will bring not only dire ruin to the lumbermen, but will throw thousands of men out of employment, and its ruinous effects cannot but affect every business man, large or small, in the state. Eighty percent of the cost of lumber represents labor. These are the conditions which confront the people of Oregon today. It almost looks like a farce to spend thousands of dollars advertising Oregon in the East as a country of great resources when the first thing that greets the new arrival is to find that millions of dollars in investments are lying absolutely idle waiting for the time to come when the railroads will again see fit to allow the state of Oregon to resume its natural business conditions." Athena Press, Athena, Oregon, October 11, 1907, page 3

HAFER READY FOR BUSINESS

Editor Morning

Mail: Under date March 13, in the Daily Medford Morning Mail, I

note with much concern the news item under the following caption, which

is printed in large, bold, black type. "Colonel Mundy Declares Off

Negotiations for P.&E."

As the article under the above title, as well as your editorials, takes occasion to pass criticism on my conduct of the dealings with Colonel Mundy regarding the Pacific & Eastern Railway, I ask for space in your paper to set forth the exact conditions which have existed for the past four months, and are still existing between Colonel Mundy and myself in connection with matters pertaining to Mundy's endeavor to purchase and take over the property of the Pacific & Eastern Railway. On November 15, 1908, I received, while in San Francisco, from A. E. Reames, attorney for Colonel Mundy, the following telegram: "Edgar Hafer, care St. Francis Hotel, San Francisco, Cal.: Imperative you come here at once. Wire tonight Postal. "(Signed) A. E. REAMES." I left San Francisco that evening for Medford, arriving here the following evening. Upon arrival I was met at the train by Mr. Reames and Colonel Mundy, who started immediately to explain his reason for having Reames wire me, and to outline his plans toward the taking over of several propositions here, of which the Pacific & Eastern Railway was one. Many Propositions.

From that time until now I have had almost daily conferences with Mundy

looking toward the solution of getting the Pacific & Eastern

entanglement straightened out and putting the road in shape so that it

could be financed to the timber and coal properties. Dozens of

propositions have been made by Mundy to handle the Pacific &

Eastern road, but not in one single instance has he ever offered to

make a proposition in writing and to back the same up with money to

show his good faith toward carrying out any one of them. This I

requested that he do before I would consider seriously any proposition

made.Friday of this week was the first time I received a written proposition which I agreed to and signed, after altering one clause wherein I was personally held responsible to bring about certain results which, had I agreed to, would have worked an imposition on the local stock and bondholders in order to bring about Mundy's desired result. The contract was nothing more than a one-sided option for thirty days, with no money consideration to show Mundy's good faith, and nothing binding to hold him to his proposition. Colonel Mundy was out at the coal properties at the time, and I signed the contract in the presence of A. E. Reames. Mr. Reames agreed that upon Mundy's return, a duplicate of the contract as altered would be signed by Mundy and turned over to me. Combination Didn't Work.

On Mundy's return he refused to consider the contract because I would

not enter into an agreement to bring about certain results advantageous

to himself, although I voluntarily lowered my price to offset the

alteration mentioned. I then requested that Mundy return to me the

contract which I had signed. This he refused to do, but said that he

would allow me to tear my name off the same, but when they came to open

their safe to secure the contract the combination of the safe suddenly

became confused and would not work. Thus I did not get the contract,

nor the privilege of taking my name off the same.As to the consideration for the purchase of the Pacific & Eastern, $30,000 for payment of current obligations would have been about the extent of Mundy's cash outlay. Balance of payments was to be made in stocks and bonds and in exchange for or assumption of present outstanding stock and bonds. I have personally devoted nearly all of my time for the last year and a half, and have expended several thousand dollars, directly and indirectly, in trying to put the Pacific & Eastern Railway in shape to be operated and extended to the timber. Our company, the Crater Lake Lumber Company, have lost their entire business and our plant is closed down today, all on account of the making of vague opportunities and then the withdrawing of them. Still Ready.

If Mundy has the cash to do business, he and I can get together for

much less than $150,000, but as for stocks and bonds, I have quite

sufficient now.Regarding your editorial suggestion as to rights of way into Medford, I have only to say that had the people of Medford furnished the Pacific & Eastern with a right of way into town it would now be a revenue-producing road, and easy to finance, and should such a right of way be furnished even now, I will start within twenty-four hours to build into town and resume passenger and freight operations. Very truly yours, (Signed) EDGAR S. HAFER. Medford Mail, March 19, 1909, page 2 The article Hafer is responding to can be found here. Lumber Mill Started Monday.

Edgar

S. Hafer, manager of the Crater Lake Lumber Company, returned Friday

evening from a trip to the extensive timber holdings of his company on

Big Butte. Mr. Hafer states that one of the mills belonging to the

company will start operation tomorrow and will continue to run

throughout the summer. A second mill is to be started as soon as it can

be made ready for operation.

The company has at present 40 men in the woods and will turn out about 30,000 feet of lumber a day. The lumber, which is to be manufactured soon, is some of the finest that the company has in its holdings. This lumber will be allowed to dry for about 60 days, and then teams will be put on to haul it to Eagle Point, from where it will be shipped over the Pacific & Eastern to this city. The company at present is receiving shipments of lumber from the Trail Lumber Company of Jacksonville. They will continue to receive lumber from that company for some time. Mr. Hafer states that everything is progressing in first-class shape as to the development of the holdings of the company in the Big Butte district. Medford Mail, May 29, 1908, page 3 Camping in the Oregon Woods.

Jim Howe, who works on the Portland Journal,

left Portland this morning for a three weeks' trip through Southern

Oregon. In company with three other newspaper men, he will be the guest

of Edgar Hafer of Medford. They will camp out in the hills for three

weeks, and will visit Crater Lake and other points of interest. Mr.

Hafer furnishes wagons, the Japanese cook, the tents, cooking outfit,

and everything else. Mrs. Edgar Hafer is now visiting in Atchison.--Atchison Globe.Topeka State Journal, Topeka, Kansas, August 31, 1908, page 3 Frank Hirasaira, who has been employed as cook at Edgar Hafer's, left for Seattle yesterday, where he will meet the lady of his choice and be married next Thursday. "Local and Personal," Medford Mail, August 20, 1909, page 5 WILL START BOX FACTORY WHEN ROAD

IS COMPLETED

"When

the first boxcar of the Pacific & Eastern reaches Butte Falls

it

will find lumber awaiting it from our mills. We expect by spring to be

operating both of our sawmills, with a combined capacity of 70,000 feet

a day, and our Medford box factory, employing a force of approximately

300 men," states C. Hafer of Council Bluffs, Ia., president of the

Crater Lake Lumber Company and father of Edgar Hafer, who is here

looking after his interests.

HAD NO TIME TO ENJOY SCENERY"I expect to sell out my interests in the East," continued Mr. Hafer, "move to Medford and personally supervise the manufacture of our lumber. The timber that we already own or have negotiations under way for totals about 15,000 acres, and eventually we intend to erect a band mill with a capacity of 125,000 feet a day. The present box factory with some improvements is adequate for some time, but it will be eventually replaced with a larger one. We will make boxes, moldings, finishings, etc. "Having been in the wholesale and retail lumber business in the central West for many years, I know just what the trade demands and can manufacture to suit the needs of each locality supplied. "There is no probability of our selling our holdings. We bought to manufacture, but have been handicapped by lack of transportation facilities. I am satisfied that the P.&E. is to be speedily constructed, and that is all that we are waiting for. "Medford has grown remarkably since my last visit and has a bright future. There is no reason why there should not be a large city here, and I think there will be--have thought so since I first saw the place eight years ago." Southern Oregonian, October 23, 1909, page 1 Mrs. Hafer Tells of Her Record-Making Trip to Crater Lake and How She Saw Only the Rocks and Stumps in the Road. MRS. EDGAR HAFER

From the map I

learn that Crater Lake is 85 miles distant from Medford, and at 7

o'clock in the morning, when driving over Bear Creek bridge, these

figures seem to be correct. But by dusk Crater Lake is physically

computed to be farther from the starting point than Halley's Comet is

from the earth at sunrise today.